Chintz fabric is making a fast comeback in recent times. Demand for chintz fabric has increased dramatically, and the fabric is fast becoming a favorite of home decorators and designers.

Traditionally, Chintz has always fallen in and out of favor. Many prefer them because they are cheap and easy to access; others love the floral design of the fabric. Having just survived a lockdown, Chintz seems to be a compromise between outdoor and indoor.

Nobody knows if the recent popularity of chintz fabric will last, but before deciding to use them, it is essential to find out what they are, the various types, and how we can take care of them.

What is Chintz Fabric?

Chintz fabric is a printed multi-color fabric mostly made from cotton. The material has a smooth, glazy finish.

Chintz is plain woven with a medium twist and a slightly bigger filling yarn with a lower twist. This type of weave gives the Chintz a crisp or stiff feel. The fabric ranges from medium to heavy weight and drapes into stiff folds.

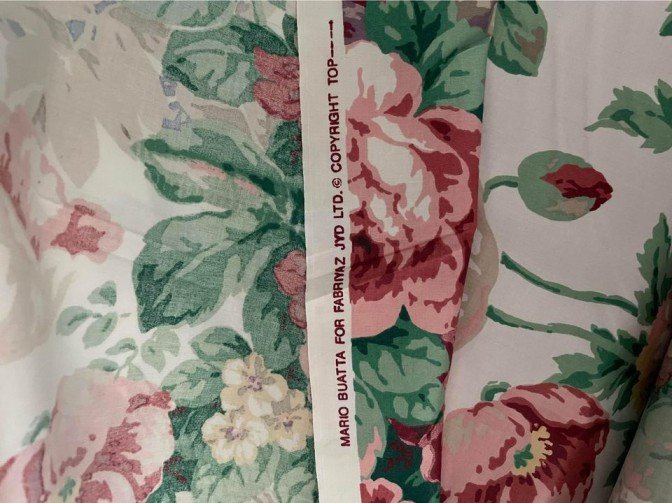

But what the fabric is most famous for is its design. Traditionally, Chintz fabric comes with intricate floral designs of multiple colors.

Like the fabric, the designs are usually bright and eye-catching, although modern designs also try to mimic the realistic look of the outdoors. The fabric patterns may seem random at first glance but usually have a geometrical arrangement, and some have even abandoned floral designs for dots and stripes.

Textile manufacturers make most Chintz fabric from pure cotton; some can come from synthetic polyester fabric or a cotton/polyester blend. Both synthetic and semi-synthetic fabric is woven in the characteristic Chintz manner to give a smooth, stiff finish.

A Brief History of Chintz Fabric

Chintz fabric originated from the Indian textile industry. The name Chintz comes from the Indian word ‘chint,’ which means ‘speckled or brilliant.’ This name refers to the shiny finish of the Chintz fabric.

Dutch and Portuguese merchants introduced the Chintz fabric to Europe in the 17th century. Its popularity soared because, unlike silk which was exclusive to the rich, Chintz was readily available.

As Chintz’s popularity began to threaten the local textile industry (an event called The Calico Wars), the governments of England and France ordered a ban on the fabric in the latter half of the 17th century.

To keep up with local demands, English manufacturers unsuccessfully tried to recreate the glaze of the original Chintz fabric. In the 1800s, the Industrial Revolution led to the production of colorfast dyes and copperplate printing, making Chintz production easy in Europe and reducing demand for Indian-produced Chintz.

However, by the 20th century, the love for Chintz fabric had begun to die, and it would remain that way until the mid-21st century, when interest in the fabric sparked up.

How Chintz Fabric is Produced

Chintz can be produced using the traditional process and the modern process. The traditional process is tedious and time-consuming but isn’t much used nowadays, while the modern process is more straightforward, faster, and more accurate.

The Traditional Process

The traditional process occurred in the following steps:

- The Calico fabric is flattened and rubbed with buffalo milk and tannin-containing fruit called myrobalan. This action is repeated several times and helps the dye bond with the fabric. The milk also gives it a smooth finish.

- A designer draws the pattern on a piece of paper. He inserts holes at specific points in the design and rubs powdered charcoal over the paper.

He places the paper over the fabric to transfer the design to get an outline. He then hand paints the outline using a mordant. The mordant helps fix the dye to the fabric and combines to produce a dark outline.

Note: In cheaper Chintz, textile workers can also use printing blocks to produce the outline on the fabric.

Second Phase

- Textile workers cover the surface with wax, excluding any area meant to be blue or green in the finished fabric.

- They immerse the fabric in an indigo vat and then air dry them. As the material dries, the fabric oxidizes to produce blue areas.

- The fabric is washed in boiling water to remove residual wax.

- Additional colors are added by hand or with block printing; the worker mixes the dyes with mordant and applies it to the fabric. He then dips the fabric in a dye bath.

Note: Traditional textile workers do not administer all the colors at once. Blue was usually the first color, followed by red, orange, and shades of pink and purple, and yellow was usually the last. Not all textile manufacturers know how to print red on Chintz fabric traditionally.

The Modern Process

Modern printing has reduced the time needed to replicate color on the Chintz fabric. The process takes the following steps:

- A graphic designer creates the design on a computer, using the appropriate scaling, and sends it over to the textile printer.

- The printer converts the document into a file that the digital printer can easily read.

- Other textile workers pre-treat the fabric in a chemical solution to make it absorb dyes better; they feed the fabric into the machine and make sure it holds fast.

- The printer moves over the fabric and creates the color. In modern printing, all colors can be printed on the fabric at once as long as they have been fed into the machine.

- The fabric is dried, streamed, and washed to check for color fastness. Then it is ironed and packaged.

Note: Textile manufacturers also glaze the modern Chintz fabric to give it its smooth, shiny appearance.

Types of Chintz Fabric

Chintz fabric is divided into two major categories. We have the fully Glazed Chintz fabric and the Semi glazed Chintz.

Fully Glazed Chintz Fabric

Glazing is a textile finishing process that adds luster and smoothness to the fabric. Textile workers immerse the fabric in a solution of either wax, starch, or resin solution; they dry the fabric in the sun or a dryer.

After which, a set of rollers called Friction calendars is passed over the fabric. Friction calendars usually have three rollers; one of the rollers is a padded roller that moves the fabric slowly between the other rollers. The other rollers move the fabric quickly, creating heat and polishing the fabric.

Note: The glaze will be permanent if the fabric is soaked in resin; starch and wax solutions tend to give temporary glazing.

Semi-glazed or Half glazed Chintz Fabric

Semi-glazed fabric only undergoes half of the process. The textile worker doesn’t fabric immerse the fabric in any solution but only passes it through the friction calendars to give it a slight polish. Because the fabric isn’t soaked in a bath, it is not as stiff as the fully glazed fabric.

Chintz Fabric Usage and Application

Chintz fabric has extensive usage and applications. Here are some applications of Chintz fabric:

Garments

Manufacturers use Chintz fabric to produce garments like blouses, skirts, nightwear, underwear, and other women’s clothing. They are also used to make shirts for both men and women. Chintz is mostly cotton, which is also great for children’s clothing.

Pillow Covers, Slipcovers, and Curtains

Chintz fabric makes very awesome pillow covers, slipcovers, and curtains. The curtains have suitable drapes and add color to a room.

Home Furnishing

One of the most popular uses of Chintz fabric has been upholstery and cushion covers. These days Chintz designs have improved to resemble more realistic floral designs properly, and the fully patterned designs can add cheer to a room.

Wallpapers

The floral design of the Chintz fabric has been used to make stunning wallpapers. Combined with an efficient floral arrangement, they can give your home a classic cherry look.

Caring For Your Chintz Fabric

Chintz fabric is glazed and cannot be treated like regular cotton fabric. Once Chintz fabric loses its glaze, it pretty much loses its beauty. The goal then is to keep the glaze as much as possible. Here are some precautions you can take to ensure your fabric last for as long as possible:

- Check the fabric care label to determine if the fabric is permanently glazed. You can wash permanently glazed Chintz fabric in a washing machine, but a temporary glazed Chintz fabric can only be dry cleaned.

- Limit how often you wash Chintz fabric. The more you wash Chintz, the more it will lose its glaze.

- Spot clean your Chintz as often as possible. Don’t forget to perform a color bleeding test before pre-Treating.

- Use a cleaning cloth to eliminate dirt. Ensure to dampen the cloth as Chintz doesn’t do well with too much moisture.

- Freshen up and deodorize the fabric to limit how much you have to wash them. Use the right products.

- Use a lint brush to remove pet hairs if you own a flurry pet.

- Store the fabric in a canvas storage bag. The canvas bag is breathable and prevents moisture and mildew buildup.

- Avoid storing them in plastic as it encourages insect attack and moisture buildup.

Conclusion

Chintz fabrics are cotton fabrics that have a fully glazed or semi-glazed finish. They’ve been widely popular for centuries, getting banned once due to their popularity. Textile manufacturers use traditional and modern printing methods to create and glaze the fabric. They have so many uses and could add a touch of cheer to your home.